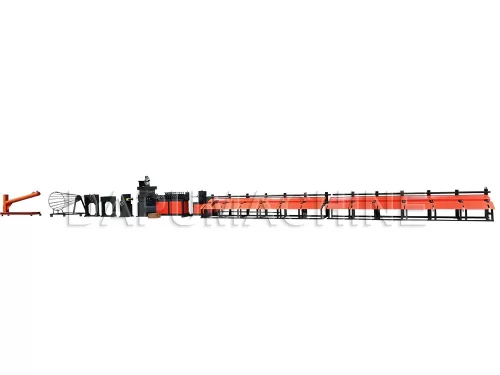

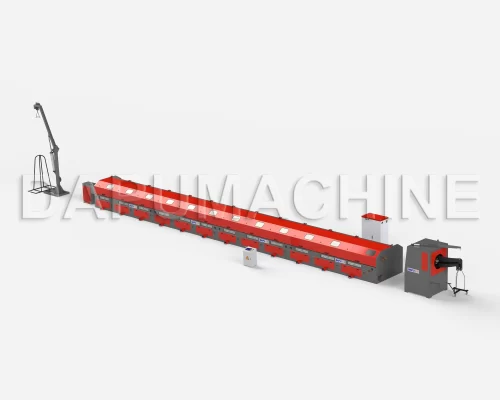

3-6mm mesh welded machine

Machine parameters

| Model | DP-FP-2500BN

(Mechanical type) |

DP-FP-2500BN+

(Pneumatic type) |

| Welding way | Motor control | Cylinder control |

| Mesh width | 2500mm (as your need) | 2500mm (as your need) |

| Wire diameter | 3-6mm | 3-6mm |

| Longitude wire space | 50-300mm | 50-300mm |

| Cross wire space | Min.50mm | Min.50mm |

| Welding electrode | 48pcs(51pcs) | 48pcs(51pcs) |

| Welding speed | Max.60-70 times/min | Max.100-120 times/min |

| Longitude wire feeding | By coil | By coil |

| Cross wire feeding | Pre-straighten and pre-cut | Pre-straighten and pre-cut |

| Welding transformer | 150kva*6pcs | 150kva*8pcs |

Machine video

Machine advantages

Mechanical type

Pneumatic type

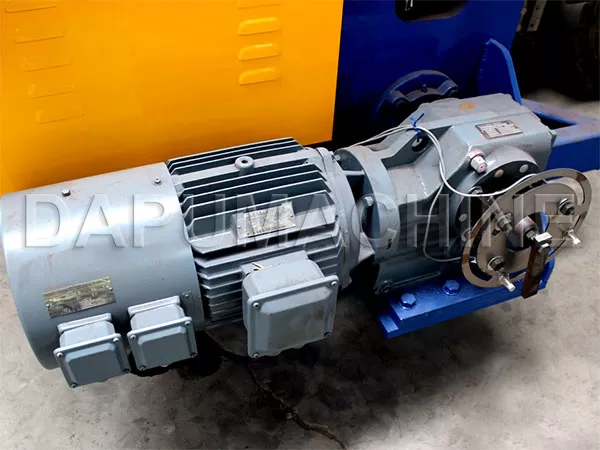

Main motor &Helical gear reducer connect the main axis directly, big transmission torque

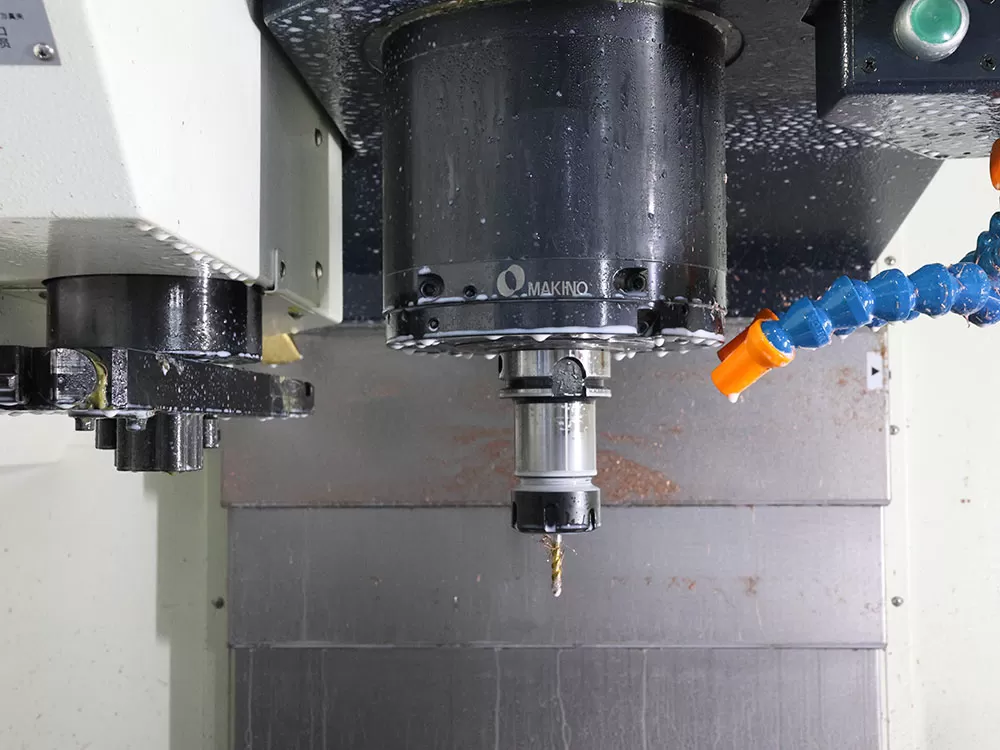

Cast water-cooling transformers and water cooling welding electrodes

The air cylinders are we developed with our Italy partner (European design), then cooperated with Japan SMC company to manufacture

Cast water-cooling transformers and water cooling welding electrodes

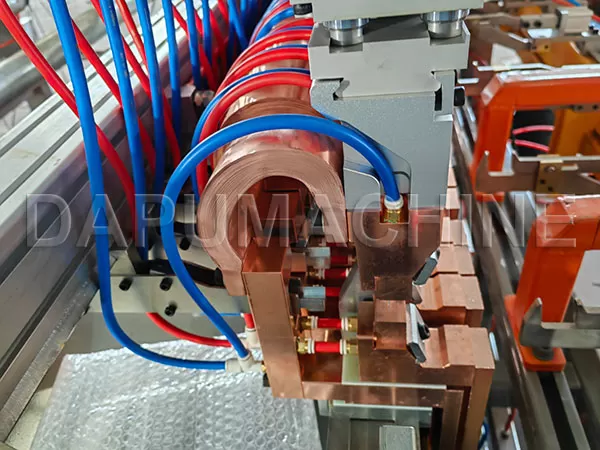

Mesh pulling system

Panasonic (Japan) servo motor for pulling mesh, more accurate.

The cable carrier is Igus brand, protect pipes and cables.

Pulling rack used J&T, the pulling distance is more accurate, less noise.

Mesh pulling space can be setting on touch screen.

Auxiliary equipment

1.Mesh-cutting-machine

2.Mesh-rolling-machine

3.Water-cooling-device

4.Air-compressor,-drier,-and-air-tank

Services and Notes

Country we sold to:

Brazil, Argentina, Colombia, Mexico, Paraguay, United States, Tunisia, South Africa, Israel, Nigeria, Tajikistan, Kazakhstan, Turkmenistan, Saudi Arabia, Malaysia, Thailand…and so on.

After-sell service including:

1.Full set installation video from A to Z,

2.Lay-out of the product line and Electric drawing.

3.Installation instruction and Manual.

24HOUR on line service for every question.

After-sell service including:

technician go aboard to installation

Cost:

1.Round trip air ticket 2. Visa cost

3.Salary 150USD/day 4.Eating and accommodation

How to maintain:

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ and Product application

What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

How to transport different type of machine?

A: Normally 1 set of machine need 1x40GP or 1x20GP+ 1x40GP container, decide by the machine type and auxiliary equipment you choose.

The production cycle of the razor barbed wire machine?

A:30-45days

How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

What’s the different between the pneumatic type welding machine and mechanical type?

A:

- The welding speed is faster.

- The quality of finished mesh is better due to same welding pressure.

- Easy to adjust mesh opening by electric-magnet value.

- Easier to maintain and repair.

Finished-mesh

Finished mesh roll