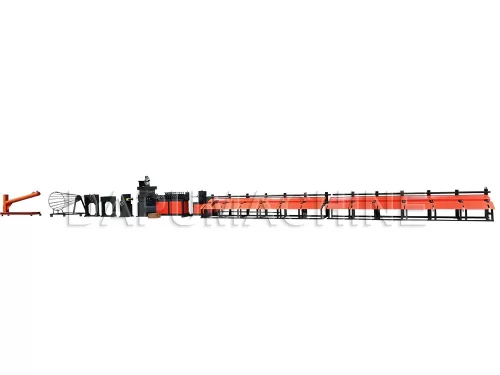

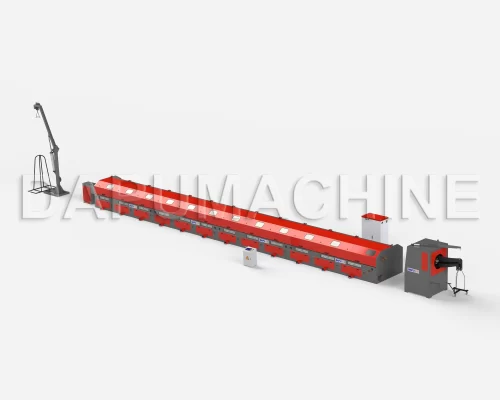

Cable tray mesh welded machine

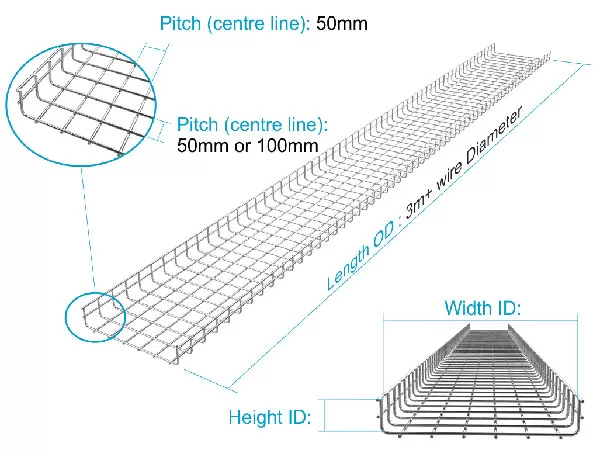

Machine parameters

| Model | DP-FP-1000A+ (Pneumatic type) |

| Wire diameter | 3-6mm |

| Line wire space | 50-300mm, Allow four 25mm |

| Cross wire space | 12.5-300mm |

| Mesh width | Max.1000mm |

| Mesh length | Max.3m |

| Welding transformer | 150kva*4pcs |

| Welding speed | Max.100-120 times/min |

| Line wire feeding way | Pre-straighten and pre-cut |

| Cross wire feeding way | Pre-straighten and pre-cut |

| Machine Weight | 4200KGS |

Machine video

Machine advantages

European design, SMC brand 45 quadra-time force energy-saving air cylinder, working speed can reach 120 strokes per miute.

Making two pieces of mesh panel at the same time.

When mesh welding, the worker can feed line wire at the same time.

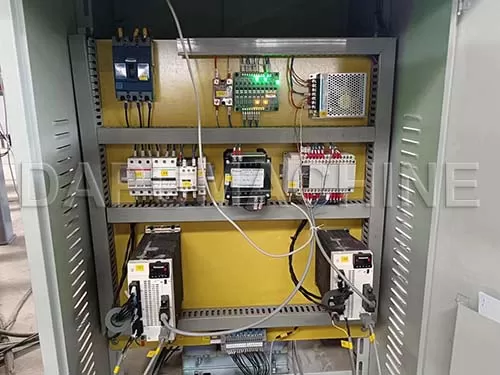

All of the electric system are famous brand.

Auxiliary equipment

Wire straightening machine 3-6H

Mesh bending machine

Services and Notes

Country we sold to:

Peru, Brazil, Argentina, Colombia, Mexico, South Africa, Turkmenistan, Saudi Arabia, Malaysia, Thailand…and so on.

After-sell service including:

1.Full set installation video from A to Z,

2.Lay-out of the product line and Electric drawing.

3.Installation instruction and Manual.

24HOUR on line service for every question.

After-sell service including:

technician go aboard to installation

Cost:

1.Round trip air ticket 2. Visa cost

3.Salary 150USD/day 4.Eating and accommodation

How to maintain:

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ and Product application

What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

How to transport different type of machine?

A: Normally 1 set of machine need 1x40GP container, decide by the machine type and auxiliary equipment you choose.

The delivery time of mesh welding machine?

A:45 days

How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

How long is the warranty period of the this machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

What’s the different between the pneumatic type welding machine and mechanical type?

A:

- The welding speed is faster, nearly double.

- The quality of finished mesh is better due to same welding pressure.

- Easy to adjust mesh opening by electric-magnet value.

- Easier to maintain and repair.

Finished-product

Finished-product