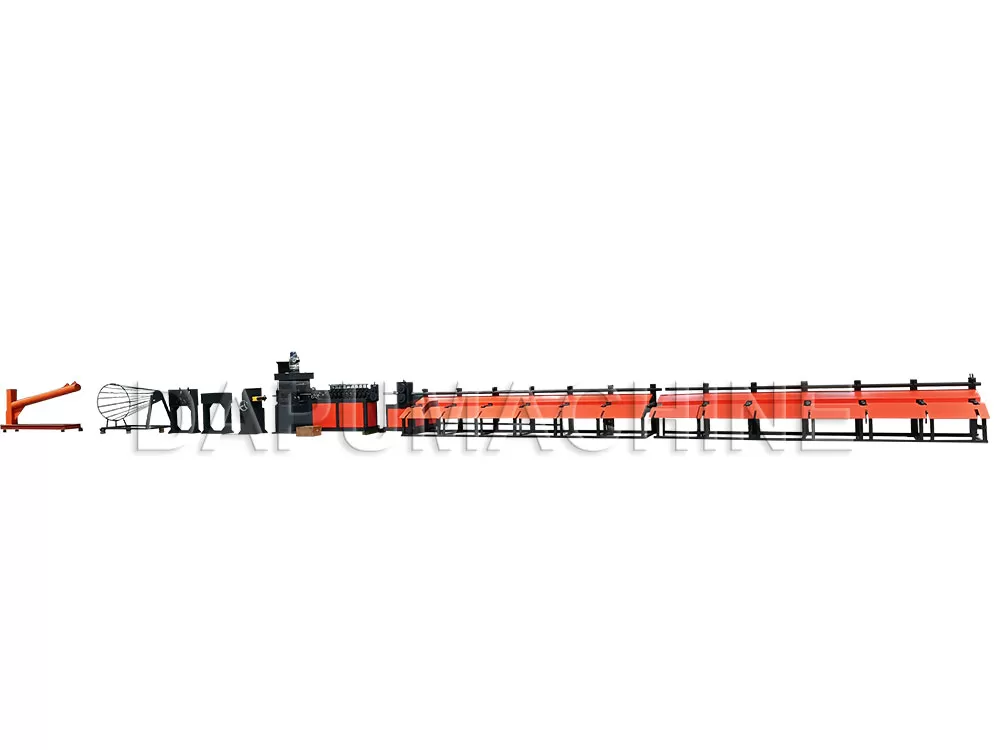

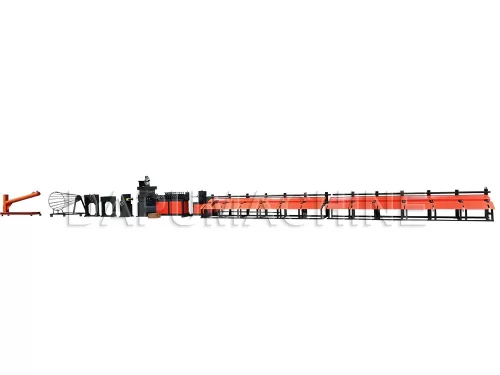

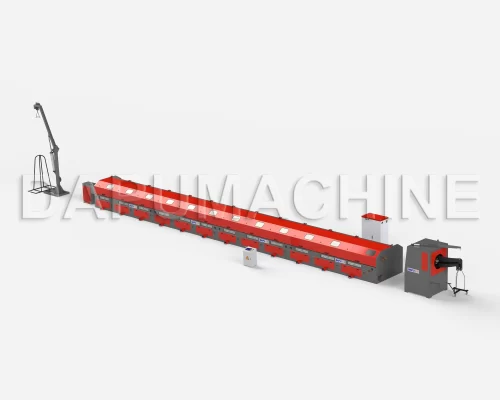

2 ribs-Ribbed bar making machine

Machine parameters

| Model | LZ-50000T |

| Max.inlet wire diameter | Φ6-14mm |

| Finished ribbed diameter | Φ5-13mm |

| Max.rolling speed | 150-180m/min |

| Coiling weight | 1T/2T/3T option |

| Max.straightening&cutting speed | 120m/min |

| Cutting length | 1-12m |

| Speed adjusting way | Frequency inverter |

| Control system | PLC+touch screen |

| Cut off error | ±5mm |

| Cutting way | Servo flying cutting |

| Rolling motor | 110kw |

| Cutting motor | 22kw (Servo flying cutting) |

| Installation length | 35*3.5m |

Machine video

Machine advantages

Speed can maximum reach to 120m per minute.

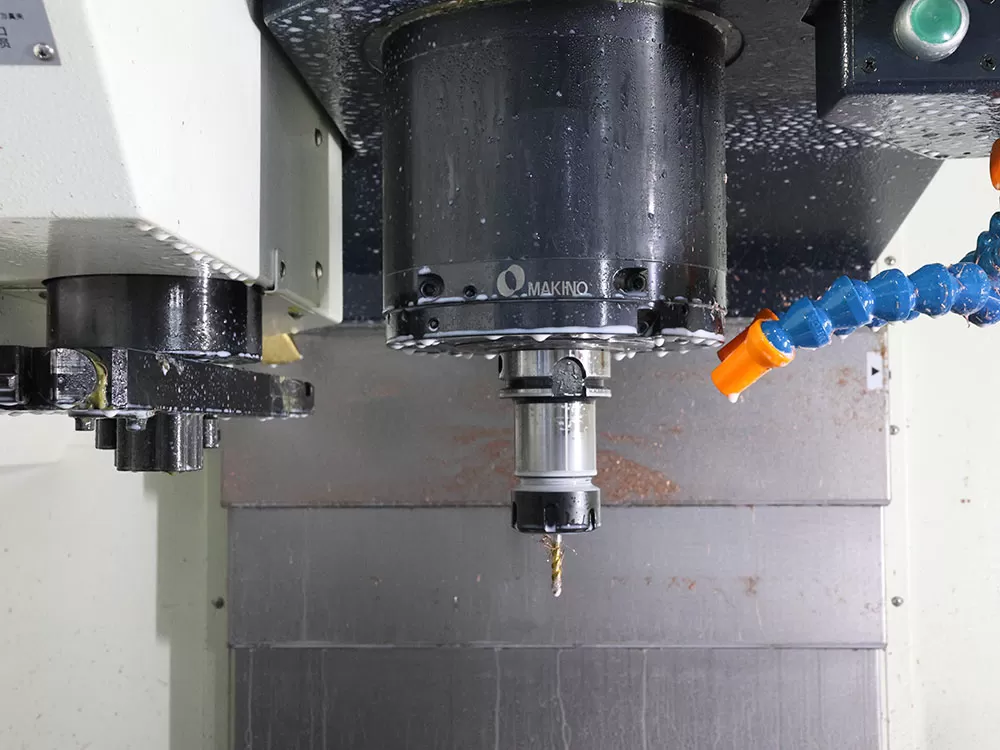

One mold can make 3-4 kinds of different ribbed bar diameter. It can be repaired and reusing for a long time.

PLC + touch screen control,easy operation. Inverter +servo motor, save electricity.

.

Services and Notes

Country we sold to:

Kuwait, Saudi Arabia, Thailand, India, Pakistan, El Salvador, Uganda, Tanzania, Kenya, United States, New Zealand, Canada, Mexico, Nicaragua, Brazil, Chile, Argentina, Guatemala, Panama, Peru, South Africa, Bhutan, Zimbabwe, etc.

After-sell service including:

1.Full set installation video from A to Z,

2.Lay-out of the product line and Electric drawing.

3.Installation instruction and Manual.

24HOUR on line service for every question.

After-sell service including:

technician go aboard to installation

Cost:

1.Round trip air ticket 2. Visa cost

3.Salary 150USD/day 4.Eating and accommodation

How to maintain:

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ and Product application

1.Can you machine produce the 16mm ribbed bars frominlet wire 18mm?

Yes. Our machine can produce.

2.What maintenance is required for two-sided rib cold drawing equipment?

Regular maintenance includes lubrication of moving parts, inspection of dies and molds for wear, and calibration of control systems to ensure optimal performance. Periodic cleaning and inspection are also important to maintain product quality and equipment longevity.

3.How can I ensure the safety of operators working with this equipment?

Operators should receive proper training on equipment operation and safety procedures. Safety guards and emergency stop features are typically installed on the equipment to prevent accidents. Regular safety audits and compliance with workplace safety regulations are essential.

4.Can your production line heating the rebar online?

Yes. We can add the heating device to heat rebars.

5.How long does the production need?

About 50 days.

6.How many grooves(specifications)can be engraved on a ribbed roller?

3-4 grooves

Finished-product