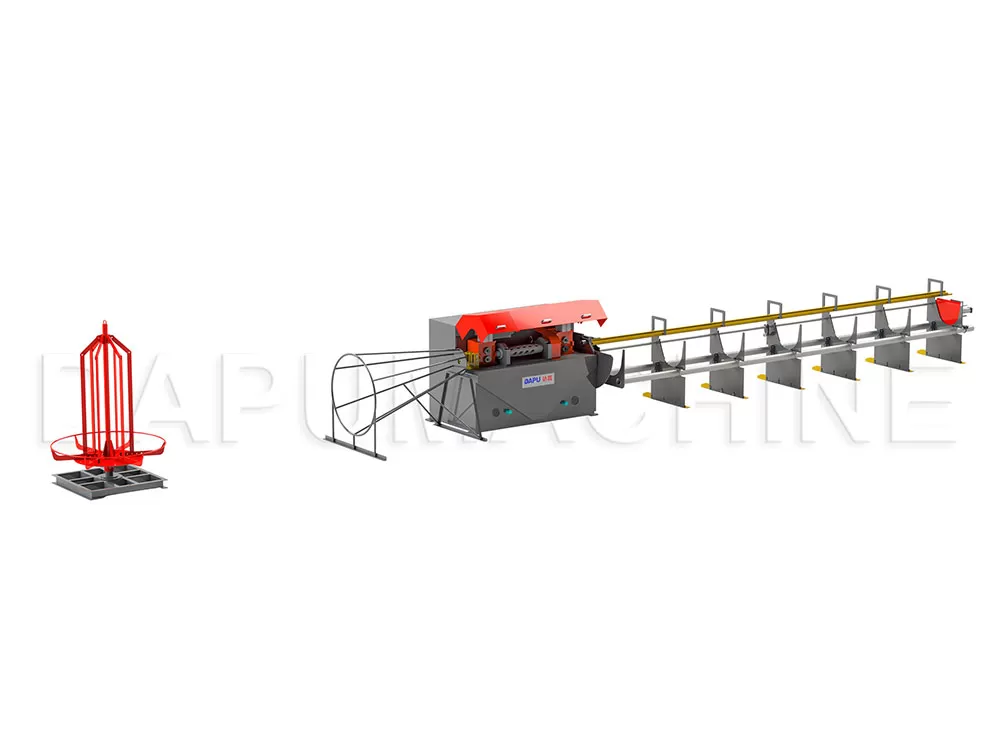

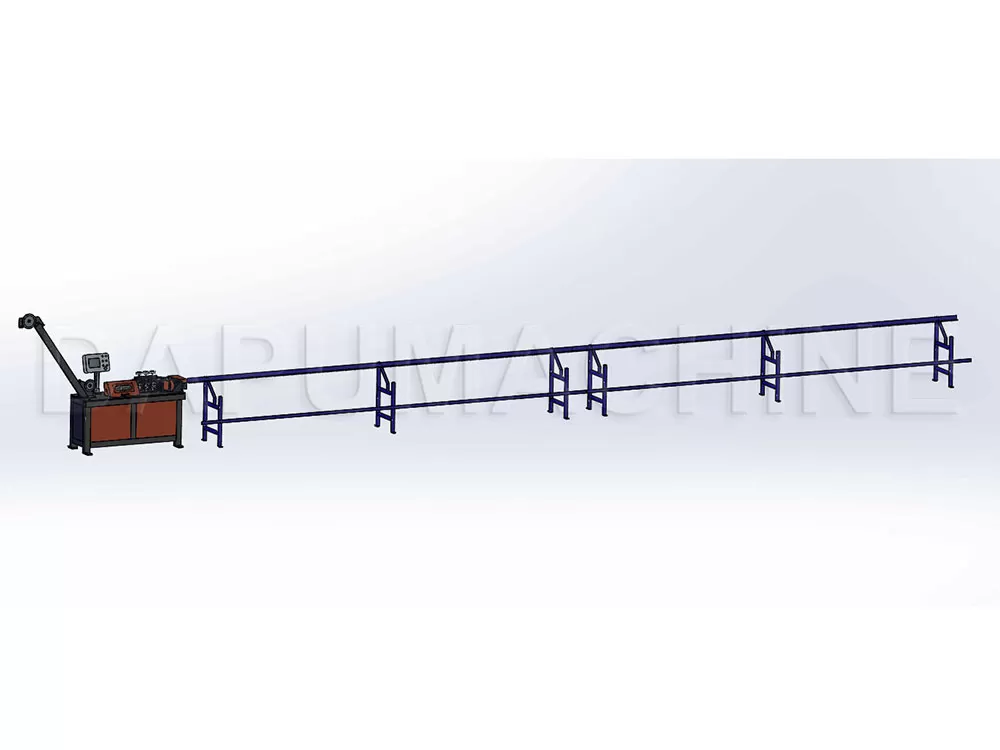

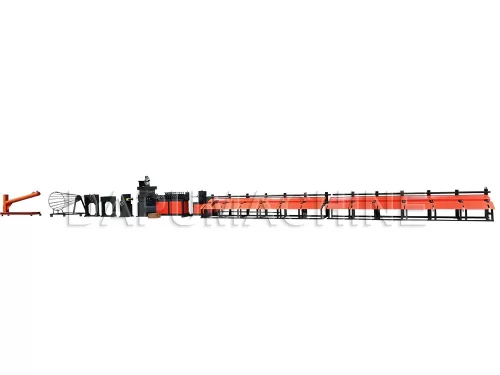

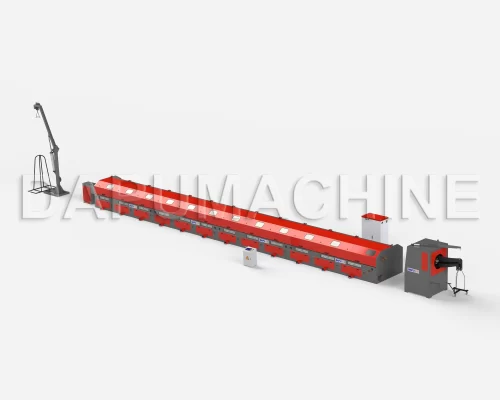

Wire straightening and cutting machine

Machine parameters

| Machine model | GT2-4H | GT3-8H | GT6-12H | GT10-16H |

| Wire thickness | 2-4mm | 3-8mm | 6-12mm | 10-16mm |

| Cutting length | 0.7-12M | 0.5-12M | 1-12M | 1-12M |

| Working speed | 40-100M/min | Max.120M/min | Max.130M/min | Max.130M/min |

| Straight motor | 1.5kw | 11kw | 37kw | 45kw |

| Cutting motor | 1.5kw | 3kw (servo motor) | 7.5kw (servo motor) | 7.5kw (servo motor) |

| Cutting accuracy | ±0.5mm | ±2mm | ≤ 2mm/m | ≤ 2mm/m |

| Machine weight | 700KGS | 2000KGS | 4700KGS | 5500KGS |

Machine video

Machine advantages

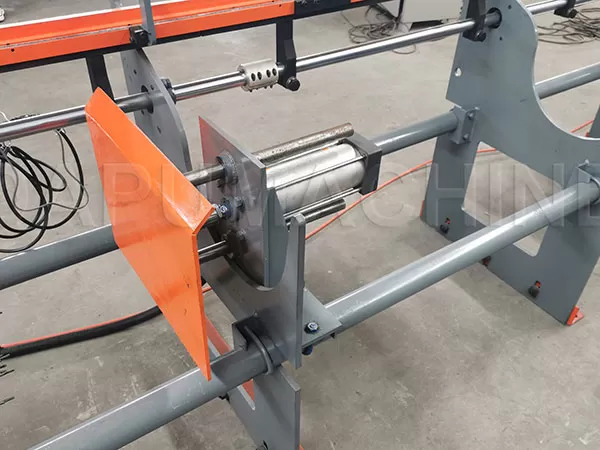

Designed straightening tube with alloy steel straightening mold

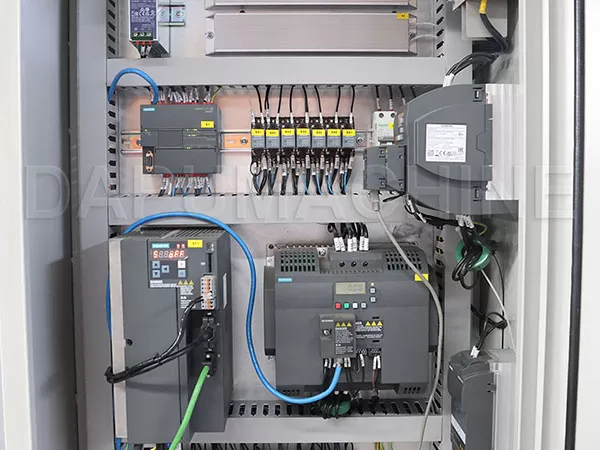

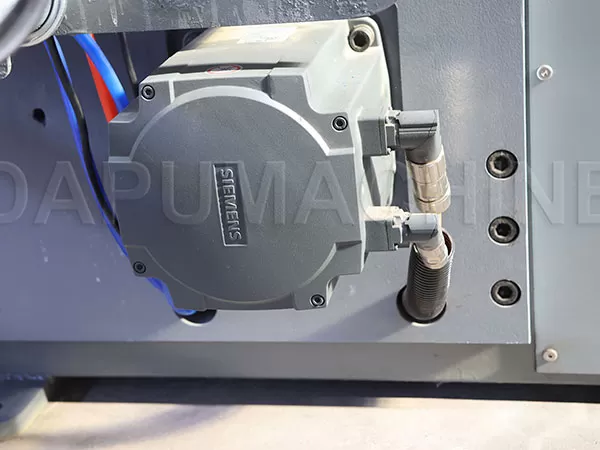

Siemens servo motor control the finished wire cutting

Wire falling bracket with pneumatic device and wire pushing device

Electric control cabinet: components are all world-famous brand

Services and Notes

Country we sold to:

Peru, Brazil, Argentina, Colombia, Mexico, South Africa, Turkmenistan, Saudi Arabia, Malaysia, Thailand…and so on.

After-sell service including:

1.Full set installation video from A to Z,

2.Lay-out of the product line and Electric drawing.

3.Installation instruction and Manual.

24HOUR on line service for every question.

After-sell service including:

technician go aboard to installation

Cost:

1.Round trip air ticket 2. Visa cost

3.Salary 150USD/day 4.Eating and accommodation

How to maintain:

Lubricate regularly as indication

Checking electric cables connection every month.

Clean the welding situation every day!

FAQ and Product application

Q: How much of the machine?

A: It depends on the material thickness, mesh opening and mesh width you want.

Q: What raw material are suitable for the machine?

A: The raw material can be galvanized sheet, iron sheet, aluminum sheet, copper sheer, stainless steel sheet etc.

Q: How to control the mesh length?

A: The mesh length can be set on the touch screen

Q: What maintenance is required for the machine?

A: Add oil to the part each day when working the machine.

Finished-product