How to use Chicken Cage Welding Machines to increase income channels

In the competitive world of poultry farming, innovation is essential for success. Having a chicken cage welding machine can not only produce cages for self-use but also can for selling cage products.

Choose the Right Machine Type

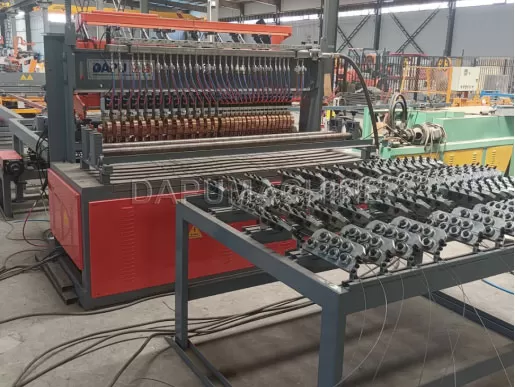

There are two main types of chicken cage welding machines to consider:

Mechanical type:

As a traditional option, mechanical chicken cage welding machines come with a wealth of production experience, ensuring smooth operation. Their affordability makes them accessible for both professional chicken cage manufacturers and poultry farmers looking to sell cages as a sidelin

Pneumatic type:

Pneumatic machines utilize specially designed air cylinders tailored for chicken cages. They can accommodate various mesh widths, including 1m, 1.2m, 1.5m, and 1.6m. As an emerging technology, pneumatic welding machines are becoming the mainstream choice due to their ease of operation and maintenance, making them popular among producers. If your budget allows, the pneumatic chicken cage welding machine is the preferred option.

Study Local Cage Mesh Specifications

To start producing cage mesh, it’s crucial to understand which specifications are most popular in your area. This knowledge will help you create best-selling products. For instance, familiarize yourself with mesh width, opening sizes, and the necessary tools for transforming mesh into cages.

If you are a poultry farmer, consider the different growth cycles of your poultry to determine the appropriate cage specifications. For manufacturers or newcomers in the industry, conducting market research and engaging with poultry farmers can provide valuable insights.

Where to Buy High-Quality Chicken Cage Welding Machines

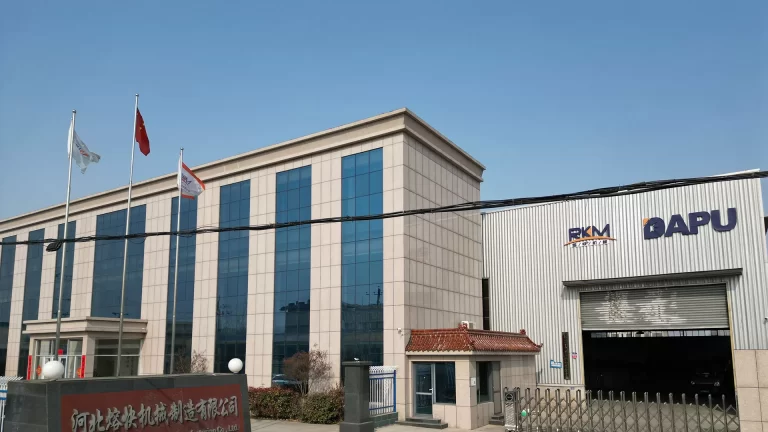

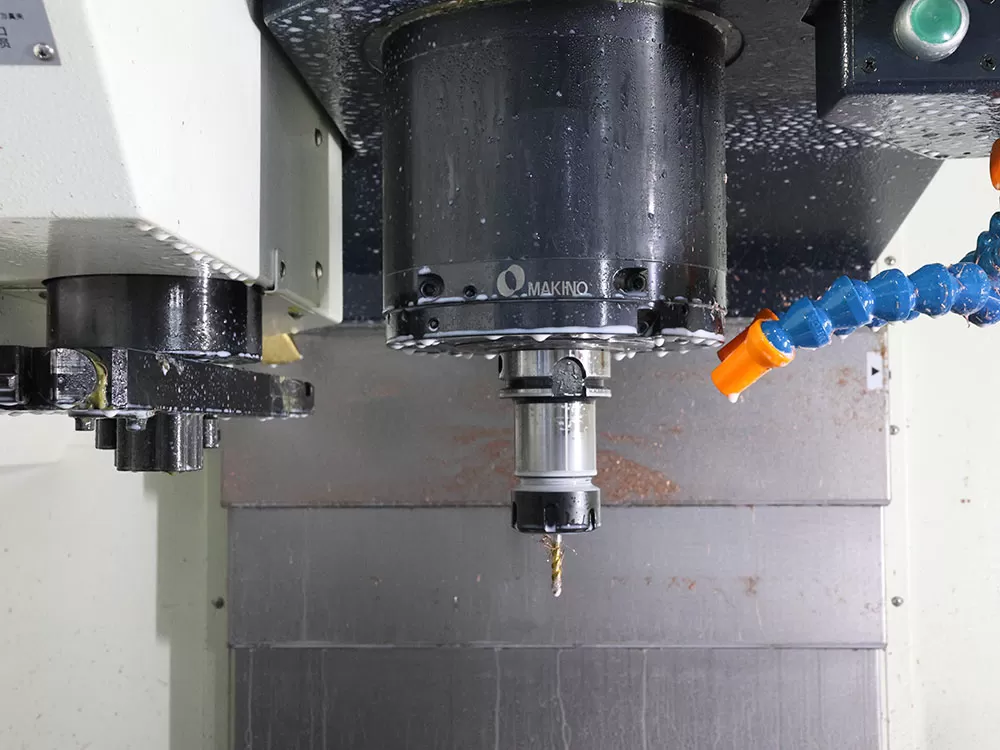

Now, let me introduce our company. DAPU has over 25 years of experience in wire mesh machine manufacturing. We specialize in producing both mechanical and pneumatic welding machines in our dedicated factories. We are committed to providing customers with the most feasible and profitable solutions. Customized machinery production according to the diverse needs of customers

In conclusion, adopting chicken cage welding machines is not just a technological upgrade—it’s a strategic move towards a more efficient, cost-effective, and sustainable poultry farming operation. Choose DAPU today and experience the difference for yourself!

Please login to write a comment after